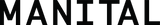

Prototyping

Everything begins with an idea: a new form, a technological innovation, the perfect harmony between technology and aesthetics. The designers work together with technicians and prototypists to include construction details and determine the exact proportions by transforming their designs ideas into functional prototypes, with a precision and final result that is equal to the product that will be eventually made in final production.

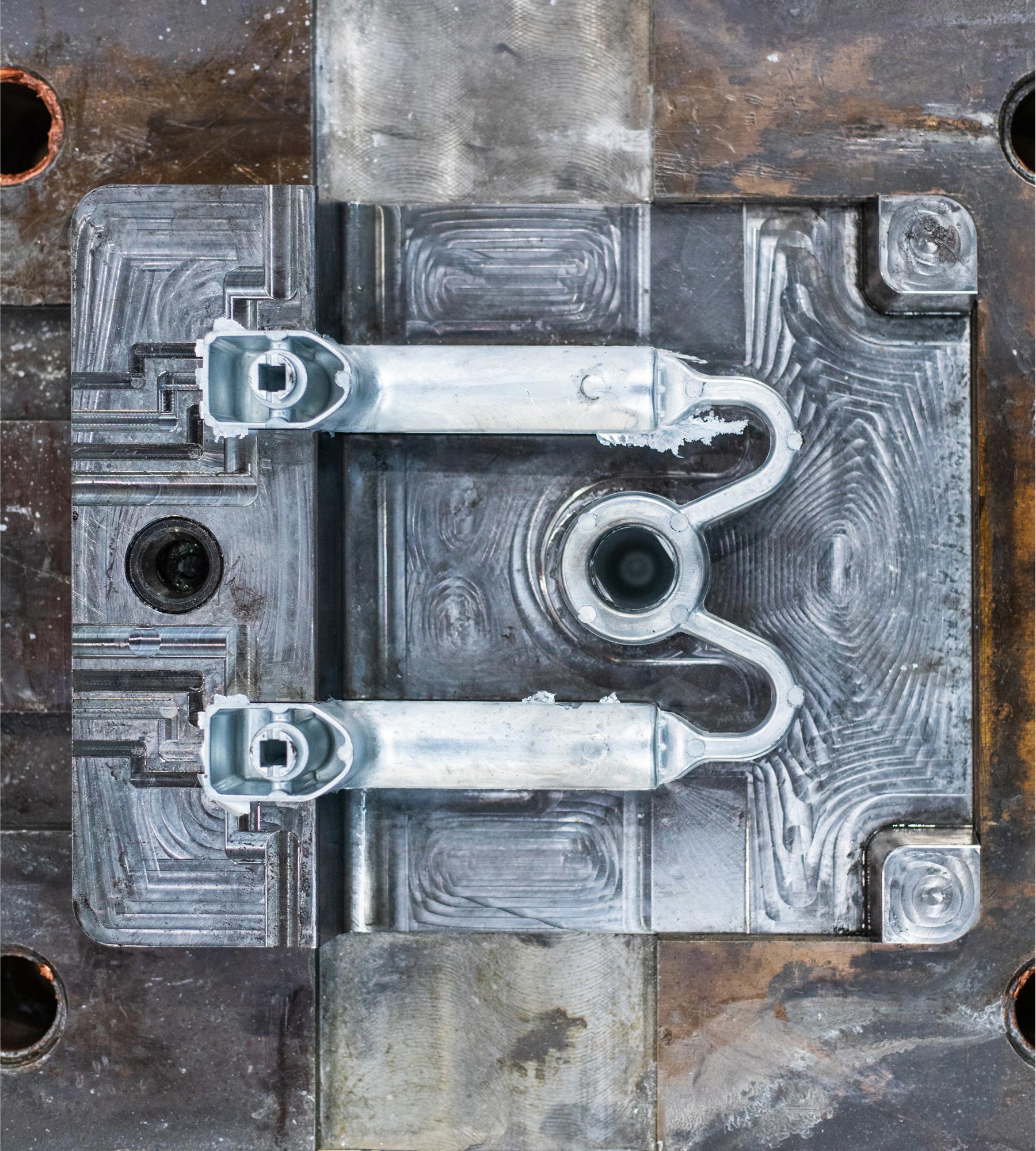

Mechanical processing

Sandblasting, grinding, vibrating, satin finishing, and polishing are the various processing phases carried out both by hand and by numerically controlled robots to obtain the desired degree of finish, while guaranteeing precision and speed. For particular handles, these processes are exclusively completed by the mastery of the human hand. The craftsman combines strength with sensitivity to obtain handcrafted masterpieces.

Finishes

Manital offers a variety of galvanic and PVD finishes. The galvanic finishing process coats the base metal of the handle with a metal of another nature, rendering it more resistant and long lasting. The galvanic finishes are offered in: chrome, nickel, bronze, and brass.

PVD or Physical Vapor Deposition technology is achieved by vaporizing metals in a vacuum, and depositing the particles onto the handle, which offers strong aesthetic, technical, and eco sustainable characteristics.